It has been an extremely good month for progress

on our XP-82 Twin Mustang Project

Center Section

I started on the installation of the center section systems on 1 January 2013. January was taken up with installing the gear boxes, and miscellaneous other heavy aluminum forgings, pulley towers, landing gear, etc., etc.

February, the progress has really started to show.

All of the landing gear mechanical linkages, arms, over-center springs, tailwheel retract cable mechanisms, gear door timing linkages and hydraulic timing valves are now completed and installed. The designer at North American in 1943 should have gotten an award for his ability to figure out and make this mechanical system work.

Left-hand landing gear retract/extension mechanism

Right-hand main retract cylinder and over center spring lock-down

Left-hand wheel well, retract cylinder and some of the hydraulics installed

Main hydraulic control panel and left-hand landing gear mechanism

Center Section Hydraulics

Most all of the hydraulic cylinders and components have been installed, along with the majority of the emergency gear extension system. We are waiting for just one last piece on the emergency system to arrive from Ron with Nautilus Machine. The hydraulic shelf, which we had built up into a subcomponent state, is now permanently installed on the center spar in the left-hand wheel well below the left-hand pilot’s fuselage. The majority of the hard lines (tubing) and fittings are now completed, attached to their applicable cylinders and components.

Landing gear and flap hydraulic lines and rudder balance cables

that transition from left-hand to right-hand wheel wells

Left-hand gear door up-lock and the hydraulic lines prior to aligning and attaching.

The lower lines are the fuel, oil and manifold pressure lines from the right-hand engine.

One of the two main gear door hydraulic cylinders is now installed, attached to the gear door retraction arm. The one for the other side is awaiting one small universal mounting bracket that attaches the cylinder to the fixed mount. We expect it any day now. All of the hydraulic lines for the gear door timing valves and gear cylinders are now completed and waiting to be attached.

One of two main gear door hydraulic cylinders installed.

We are missing only two hydraulic components, both of which have been located and are now on order--the relief unloader valve and the hydraulic dump valve. The relief unloader valve’s function is to control the hydraulic pressure and flow while some hydraulic function is operating--i.e., flaps, gear, doors, etc.--and to drop the system pressure to idle when there is no need for hydraulic pressure. The dump valve returns all gear-up pressure through a large return line directly back to the hydraulic tank when emergency gear-down is selected. With normal hydraulic gear-down, the gear-up static hydraulic pressure has to be pushed back through the gear selector and then returned back to the hydraulic tank. The dump valve makes the emergency gear-down hydraulic fluid flow a lot more easily. I contributed out of my Kissimmee surplus stock hundreds of new AN fittings for all of the hydraulics.

Right-hand wheel well with all of the landing gear mechanism installed;

the four upper lines are right-hand to left-hand cockpit

engine instrument lines prior to attaching.

Center Section Mechanical Systems

The four rudder balance cables that connect both cockpits and the pulley mounts are now permanently installed.

Left-hand pulley tower, rudder balance cable and landing gear

retract/extension forging and bellcrank installed.

Main tire temporarily in place to confirm no hydraulic line interference.

Fuel Supply and Fuel, Oil and Manifold Pressure Indicator Systems

The last week of February, I installed all of the oil, fuel, and manifold indicator pressure lines from the right-hand cockpit to the left-hand pilot’s cockpit We have started working on the mounts for the fuel selectors and the fuel shut-offs that mount in both wheel wells under the two cockpits. All of these mounts were severely corroded beyond economical repair from years in the weather in the Fairbanks scrap yard and the Colorado storage yard.

Weezie and I have completed all of the elevator and rudder primary control cables for both fuselages. I contributed out of my Kissimmee stock all of the cable, fittings, turnbuckles and additional pulleys required. (Nearly three thousand dollar’s worth)

New elevator and rudder cables

Pilot and co-pilot stick handles and landing gear handles

Outboard Wings

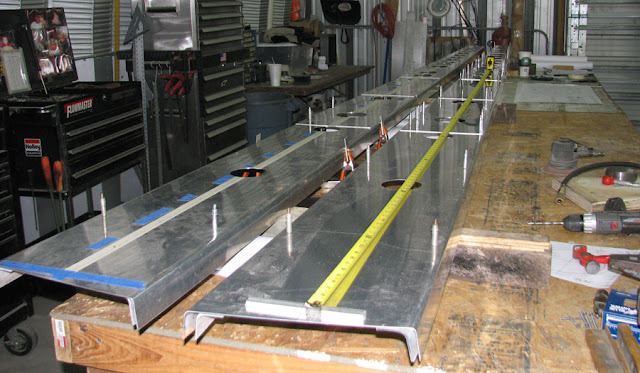

Paul, Randall, Ayman and Jeremy have been making substantial progress on the three spars in each wing and all of the leading edge ribs. Weezie has taken all of these parts to Thrush Aircraft in Albany, GA, to have this large first batch heat treated. The crushed XP-82 wings and the P-51H wing (the same wing as our XP-82 with the exception of the gear well change) we got from the Soplata and Odgers yards have been priceless for our copy patterns. The forward spars and the leading edge ribs have now been final fitted and drilled and the spars painted and riveted together.

Outboard wing leading edge spars with one set of nose ribs set up.

The second set of nose ribs are all completed.

Paul and Ayman shooting the left-hand forward wing spar.

Bumps in the Road

After six months of drought, we have gotten our total rainfall for the year in just the last two weeks of February. We are all having to wear water wings so we don’t drown. Close to 20” for the month of February alone.

Many thanks to Thrush Aircraft, Ron, Mid-Florida Propeller,

Cullen, Vic, John, Ken and Gerald ... plus all

of the employees and other volunteers who have

worked on our XP-82 project.

The Katz

"Life is good being Hangar Katz"

Rivet & Allison

Thankx!

Tom

+men+to+put+these+in..jpg)

.jpg)