2013 ... A New Year for Our XP-82 Twin Mustang

Center Section

Finally, the majority of the sheet metal work on the center section is completed. We have been busy installing systems, quadrant transfer cables, main gear, gear retract and extension mechanisms, fuel shut-offs, stick towers, center line bomb rack, gear door castings, etc., etc.

The installation of these systems will go on for the next couple of months, and when completed, we can finish the installation of the leading edge, and conclude skinning of the bottom gear wells, gun bay panels, the top left and right aft fuel bay panels, and the gun and ammunition bays. This completion of the skinning will not take more than a week after the center section is taken out of its fixture.

A Milestone Passed on 30 January 2013

The Main Landing Gear was Permanently Installed in the Center Section

Left-hand Main Landing Gear Installed

Right-hand Main Landing Gear Installed

Right-hand Aileron and Elevator Center Section Bellcranks

Left-hand Aileron and Elevator Center Section Bellcranks

Cable Phenolics (10 Total)

Left-hand Pulley Tower and Landing Gear Retract Arm Installed

Right-hand Pulley Tower and Landing Gear Retract Arm Installed

Left-hand Pilot's Stick Tower Installed

Right-hand Pilot's Stick Tower Installed

Fuselages

When the above work is completed, we will mount the two fuselages on the center section and start to mate the two forward fuselages with the aft fuselages and the horizontal and both vertical stabilizers. The attachment of the rear fuselage extensions will be a challenge as we have no data on the attachment angles of the forward bulkhead. Fortunately we have all of the loft drawings from North American, so the set up will not be that difficult.

Bellcranks and Landing Gear Door Extension Retraction Arms

Weezie has been spending days pulling up all of the drawings for spars and ribs for the outboard wings, and bringing them downtown to the print shop to enlarge them to full scale. She did the same thing for the center section ribs, which made the task easier of forming the bending blocks over which we form the aluminum with our 220-ton rubber press.

A special “Thank You” to Tom Wilson from The Curtiss Hawks Factory in Sugar Hill, GA, for supplying us with the outboard “T” sections for the wing center spar caps.

Outboard Wings

On 1 January 13 the crew--Paul, Randall, Ayman and Jeremy--started on the two outboard wings. Within four weeks, they had all the parts for the six spars for both wings basically completed, less the four inboard taper-milled spar caps. Vic Peres (Erie) is milling these for us out of one of our remaining billets used for the center section spar caps. These are special pieces as the “T” part of the spar cap tapers down on thicknesses as it transitions from the root to the center of the wingspan.

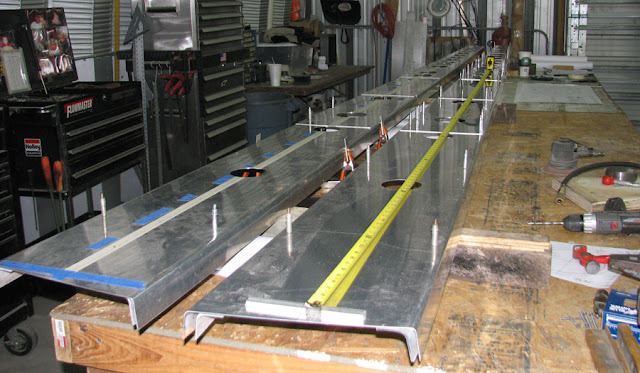

Two Forward Outboard Wing Spars

Leading Edge Ribs Being Fitted to the Two Forward Outboard Wing Spars

Canopy Find

A couple of weeks ago Weezie got a voice mail on her phone that a man in Charlotte, NC, had found a canopy for a P-82. I immediately called him and questioned, “Is it really a P-82 canopy?” and he assured me that it was by part number. Considering that there are only four civilian owned P-82 canopies in existence, our two and Pat Harker’s two, and one extremely damaged one out of the Alaska crash site, finding an additional P-82 canopy was like finding the proverbial needle in a haystack. The P-82 canopies are completely unlike any of the P-51 Mustang series, so I made an immediate special trip to Charlotte to purchase the canopy. The owner didn’t want any money for it; he just wanted it to go to a good home. Thank you, Josh.

The Katz

"Next time you go, please take me with you." - Rivet

Thankx!

Tom

+men+to+put+these+in..jpg)

.jpg)

Nice blog..! I really loved reading through this article... Thanks for sharing such an amazing post with us and keep blogging.

ReplyDeleteHelical Rotary Actuator | Rotary Actuators Manufacturers