What a fabulous year it has been working on the XP-82

Systems

Since 15 January 2013 Weezie and I have been installing systems in the center section and both fuselages at a rapid pace. We started sub-assembling all the systems about 18 months ago, i.e., gear and retract mechanisms, electrical, quadrants, control and trim cables, trim boxes, hydraulic components and lines, stick/pedal assemblies, flap, and coolant tube systems; and then sealing them in boxes awaiting installation(s). The shelves are getting emptier and emptier every day.

Left-hand Cockpit with Systems Installed

Wings

The entire team--Paul, Randall, Ayman, Jeremy and Tim--have been steadily working on the two outboard wings attached to the center section prior to their going onto the steel fixture. The preliminary drill-up of the skins with #40 drill holes (tiny) on the right-hand wing is now completed. All of the fuel bay hat channels and stringers in the left-hand wing are nearing completion. By the end of January, we project that both wings will be in the steel fixture for final sweep, dihedral and wash-out alignment (see our May issue for descriptions) and final drill-up to size and final riveting.

Right-hand Wing

Left-hand Wing

Control Systems

The final fitting of all the control cables and pulleys in both fuselages and center section is now completed back to the tail assembly factory breaks in the aft fuselages. We are still waiting for three parts from the machine shop to complete the installation of the rudder pedal assemblies in the right-hand fuselage. We are now just completing the canopy opening/closing and jettison systems. As mentioned last month regarding the canopy trucks, one of the six failed NDI (non destructive inspection) due to cracks so small that one cannot see them even using a magnifying glass. One of our contract machine shops is now machining a replacement for us.

Canopy Trucks

Coolant Systems & Tubes

All of our multi-layer coolant tube insulation was delivered the second week of December. A beautiful job matching the original color, texture and stitch patterns. We just completed installing all of the insulated 2” and 1.25” tubes from the firewall(s) back to just forward of where the radiators mount.

Floorboard Molds

In order to make the compound shape floorboard molds, I have epoxy-glued salvageable parts from each damaged floorboard together to make a complete pair of left- and right-hand floorboards to serve as molds to be used to make four new panels. I should have these two molds completed some time this coming January.

Floorboards

As critical as we have been on matching everything back to as original on this XP-82 restoration--paint colors, 442 rivets, #1 cad plate, etc., etc., we had to make a modification to the original phenolic floorboards. We have a number of original phenolic floorboards, and every one of them has fracture-failure repairs made when this aircraft was in service.

Phenolic is a laminated cotton, somewhat like fiberglass, but no where near as strong. They all had failed where the pilots had to stand on the floor panels when entering and exiting the cockpits. I have come up with a non original idea, (Pat Harker actually did this mod to his F-82E), to make the floorboards out of carbon fiber with a layer of the correct color and weave cotton laminated on the exterior top and bottom of each surface giving the appearance that each panel is still phenolic. With the carbon fiber laminated in between the two exterior cotton layers, the finished floorboards will look identical to the original, but will be many times as strong.

Heat Exchangers (Oil Coolers)/Miscellaneous Parts

Martin Radiator has started on our two heat exchangers. Pictured are the four end-cap brass rings that we had machined for Martin. Also, our last needed wing jack point was delivered and is now installed.

We are awaiting the last two of five flap control arms to be delivered in January. When they arrive, we can complete the center section to outboard wing flap tube structure and install them on the aft center section spar located under each fuselage.

9" Heat Exchanger Brass Rings

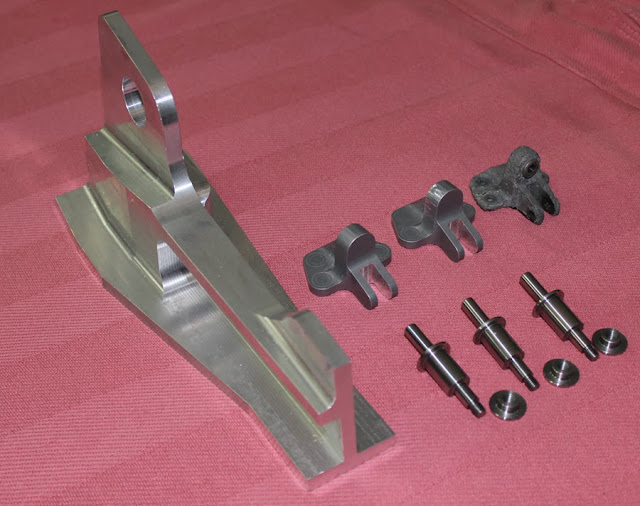

New machined jack point, gear door stops and rudder pedal adjusters

Wing Jack Point Set-up and Drilled on Rib

Rudder Pedal Assembly

Completed Flap Control Arms

A special thank you to Michael O’Leary, Editor of Warbirds International magazine, for the very nice article on our XP-82 restoration. And, Larry Kelley, B-25 Panchito, contributed the special N.O.S. rubber mounts for our radio racks. Thanks Larry and Michael.

The Katz

Merry Christmas & Happy New Year from Allison, Rivet

and the XP-82 Team

Thankx

Tom

Looking great! Keep the pics rolling!

ReplyDeleteThank you. Will keep them coming every month til she is airborne.

ReplyDeleteOrange cats are very mosey LOL Great job would love to come up there and see the work Scott

DeleteGreat work!!

ReplyDeleteWaiting to see it fly!!

Really hard work dear. Thanks for sharing it. steel caster wheels & heavy duty casters low profile

ReplyDelete